Adhered Masonry Veneers including schist cladding, stone veneer, and brick cladding.

Whether your project uses brick slip, stone veneer, or tiles, the installation process can be as simple as glueing the decorative masonry to a wall.

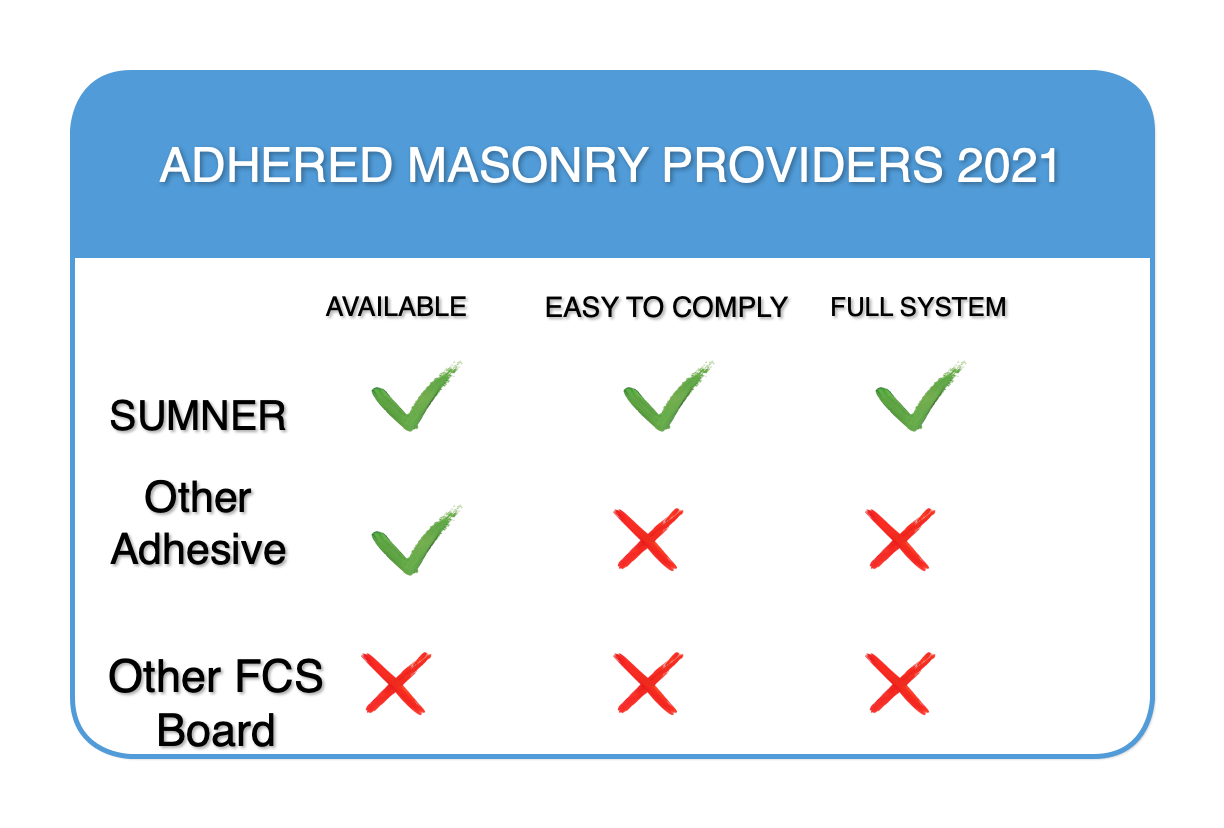

Adhered masonry has three advantages: It costs less than foot-loaded masonry, there is lower earthquake risk, and with our SUMNER® Adhered Masonry Veneer system, it is easier to gain council consent. These three factors have contributed to its popularity.

SUMNER® - Our adhered masonry solution

SUMNER Schist Cladding System

SUMNER® is the best system on the market for adhered masonry veneer.

For over 15 years, our SUMNER® system has been the go-to choice for builders across New Zealand, offering a cost-effective solution. Its reliability and proven track record in protecting clients and projects from cladding failures have made it a preferred option. For customers seeking to save costs, choosing a less expensive stone over an inferior system is a wise decision.

SUMNER® also provides masonry finishes that are delivered ready to install, along with the adhesive, board, tape, and components needed to complete your project successfully (see system photo).

Every component has been developed and tested to guarantee that installations are weatherproof, structurally sound, compliant with building codes, and free of problems. SUMNER® adhesives and board work together as a system, whereas other tile adhesives may be limited to 32 kg and unsuitable for installations over three meters in height. These limitations are often ignored, so we do not endorse product substitution, as it could result in issues or failures.

Focus on Irrecular Stonework

A SELECTION OF IRREGULAR EUROPEAN STONES.

BE INSPIRED

Many clients are unaware of the fantastic stone finishes available.

SUMNER® has consolidated a collection of the world's more prestigious irregular-shaped stones that deserve consideration. Premium products used to enhance architectural homes, hotels, and resorts worldwide.

Phone now to discuss.

WHAT IS TRENDING

This year, clients have incorporated schist and irregular stonework into their projects.

Our Strata Grey schist stands out for its stunning appearance and affordability, along with our version of Waiheke Stone. You can delve deeper into our supply and application of Waiheke Stone veneer at 5 Karu St, Oneroa, Waiheke Island..

SUMNER system benefits

Builders

- Receive pre-cladding that is fast and easy to assemble.

- SUMNER® Board is asbestos-free!

- HEAVY DUTY core fluted plastic battens, with horizontal battens to prevent wall sagging.

Architects

Avoid time navigating third-party specification websites when it is free and easy to download right here:- Download our SUMNER Product Technical Statement, which demonstrates compliance with the relevant building code clauses.

- Download full CAD details for Revit or as DWG file or PDF.

- Download SUMNER® written specification

- Avoid unwarrantable non-compliant methods.

Customers

- Can choose from our large selection of adhered masonry veneers.

- Receive competitive market pricing.

- Receive warranties that our quality products are fit for purpose, backed by more than 20 years of industry experience.

WAIKATO PROJECT RECENTLY COMPLETED

Why SUMNER?

- We specialise in adhered masonry veneers.

- Avoid adhesion failures. Use SUMNER Grip Plus, our highly modified masonry veneer adhesive.

- We only use best practise and recommend a constructed cavity in favour of direct fix.

- We supply quality system products needed for successful, long-lasting installations.

- We have more experience with adhered masonry than any other New Zealand company.

- SUMNER Board is denser than other boards, with a 1420 kg per cubic metre density.

- We have high-end finishes exclusive to SUMNER.

- Our finishes are designed to add value.

- Our VERMINI battens are heavy duty and fluted to manage moisture, prevent vermin, are non-pourous to avoid mould.

- Our system is designed and used specifically for masonry veneer.

- We value customer confidence and return business.

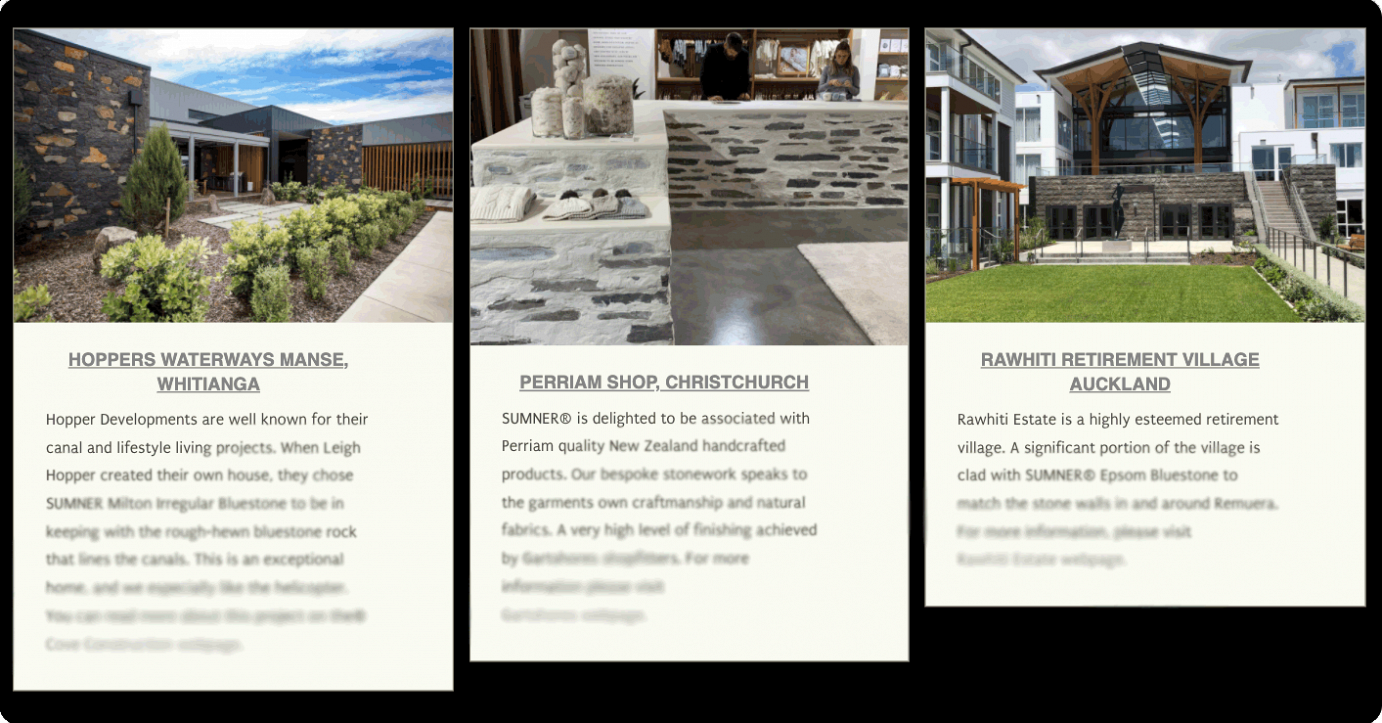

SUMNER® Projects for inspiration

Click on the gallery below to view photos from a selection of our work.

SUMNER® adhered masonry is used on commercial and residential projects throughout New Zealand. Many installations include columns or chimneys, which require external corners. To discuss this further, we have an example of stone veneer columns which came up fantastic.

Stone columns using modular panels

Below are two methods to successfully install modular panels to columns. Timber-framed columns need to suit our stone panels, and we recommend discussing this with our sales staff.

Solid L Corners

Solid-L corner units are pre-formed to wrap around a column and are available for most stones. This technique is slightly more expensive but well worth the cost (see video).

Natural Ends

We use Natural-End panels to tile around columns. The natural end extends past the edge of the column, with each adjacent side tiled similarly. Repeat until all four sides of the column have their first course of stone. The finished column will look similar using Solid L Corners but costs less.

QUEENSTOWN PROJECT NEARING COMPLETION

Adhered masonry can create breathtaking features, such as the large stone chimneys of bespoke mansions or the entrance pillars to prestigious subdivisions whose initials monogram the stonewalls. Adhered masonry is in the entrance foyers of grand hotels and wraps around the warm interior stone fireplaces of family homes. Sturdy bluestone is a popular masonry veneer for boundary walls. Recently, we have even been using recycled red brick slip to recreate New York styled apartments' walls. The value of adhered masonry is in its appearance. However, if installed incorrectly, without using the correct products or method, then it can come unstuck. We highly recommend using SUMNER® adhesive products. Also, if you think your project will benefit from formal installation training, please contact us. The following photos are from some of our training days:

SUMNER® Installer Training

SUMNER® averages six training days per year in which installers are instructed in both theory and practical application. Our training is regarded as the best in the industry and is a must for both professionals and DIY. Learn the techniques to ensure your fitment lasts the test of time. Contact our office to enrol for our next training day in your region. Below are photos from previous training days.

Where to from here?

We highly recommend looking at our products page where we place photos and videos for all our stones. We have an architectural office in Auckland where you are welcome to view our products. Alternatively if you are in the South Island a CMS representative can call in to discuss your project. All our details can be found on SUMNER's Contact webpage. If you are interested in using SUMNER® products please phone us to discuss.

Did you know?

SUMNER's system can be used to comply and install other stone veneers. Please refer to our System Partner page for more details.

Specifiers Resources

SUMNER® only uses the best products, and we believe in quality projects. You can specify SUMNER® adhered masonry veneer with confidence by using our written specification below:

SUMNER 1.0.2 Written Specification for adhered masonry veneer.Full system details and drawings can be requested from our document page.

Brick Veneer

For clients using brick slip we also recommend Stelleria and CLICKBRICK®. CLICKBRICK® is a modular panel pre-fabricated off site suitable for larger projects such as hotels, appartments or retirement homes. This panel differs from adhered masonry as it is installed with screws not adhesive.